Automation for Industrial Processes

Custom-made special equipment or standard equipment for:

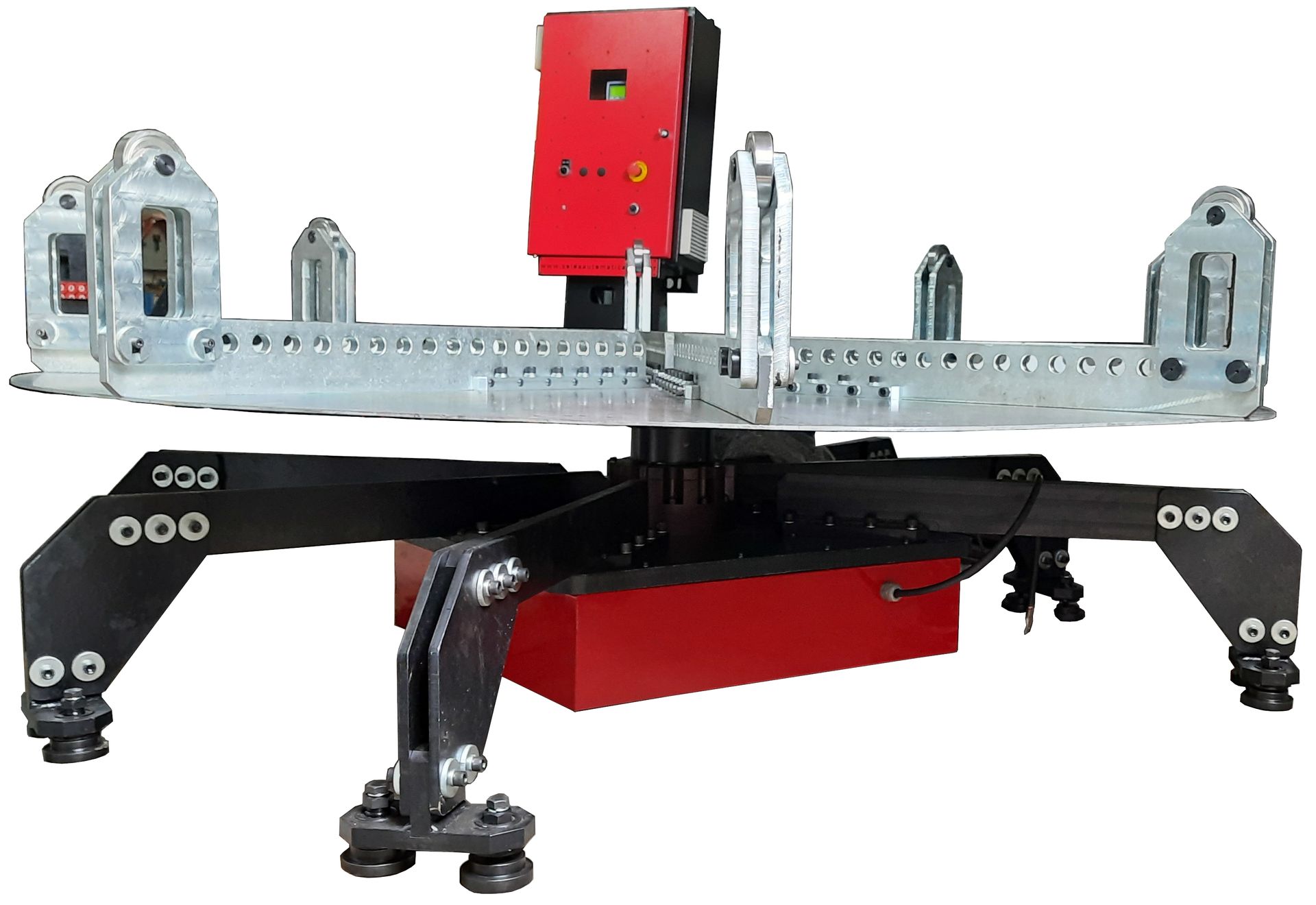

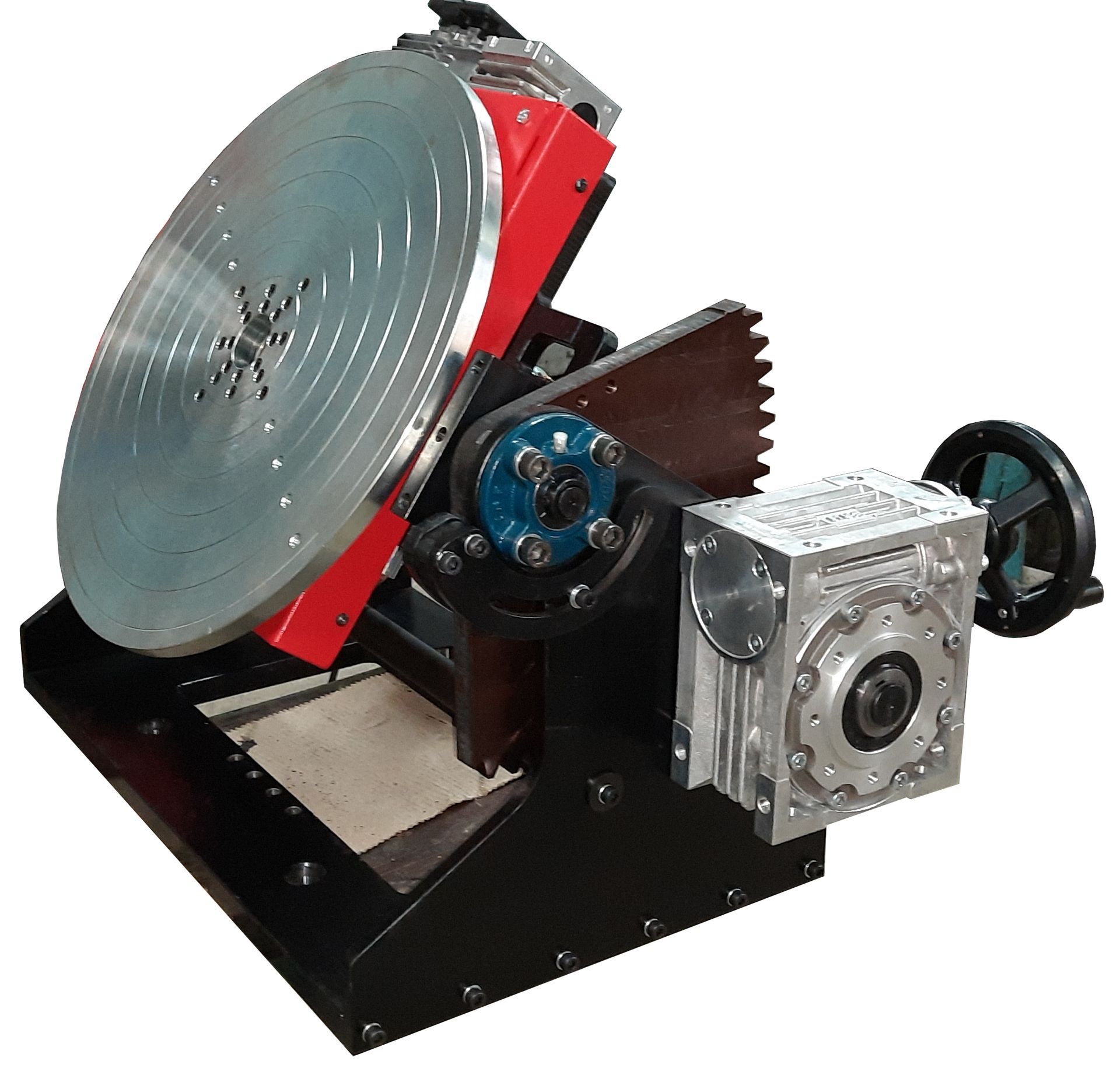

Arc Welding (MIG, TIG and Submerged Arc) / Plasma Cutting / Projection Welding

Waterjet Cutting / Induction Heating and Brazing

Assembly and Handling

Robotic Cells

Welding Tables (Modular Quick Clamping System)

NR 12: Adaptations and Reports

Risk Analysis, Security Design, Implementation of Protection Measures and Documentation

Services and Products for Integrators and

Equipment manufacturers

Mechanical and Electrical Projects, Devices, Equipment, Parts and Templates

Robotic Cells: Positioners, Automatic Curtains and Windows, Tables for Quick Change of Templates

Over 35 years of experience manufacturing industrial automation equipment

Own machining

Always focused on providing the best cost-benefit solution,

Flexibility: Equipment adapted to the specific needs of each client

Innovation: We use the latest technologies to develop high-performance and durable equipment

Compliance: Equipment manufactured in compliance with applicable technical standards and regulations, ensuring safety and quality.

Always meeting production and quality expectations.